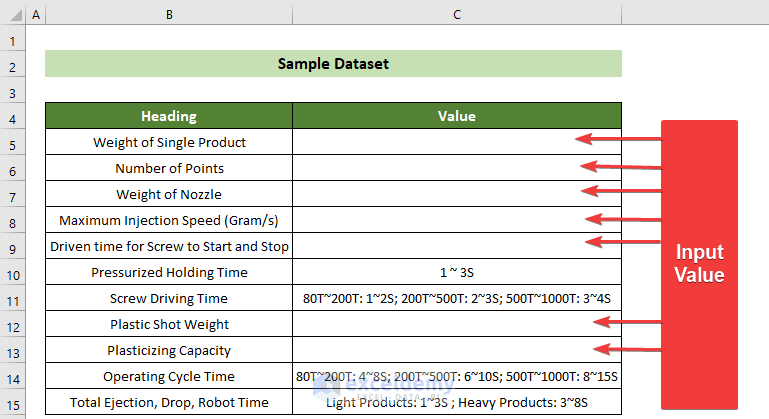

Method 1 – Input the Required Values

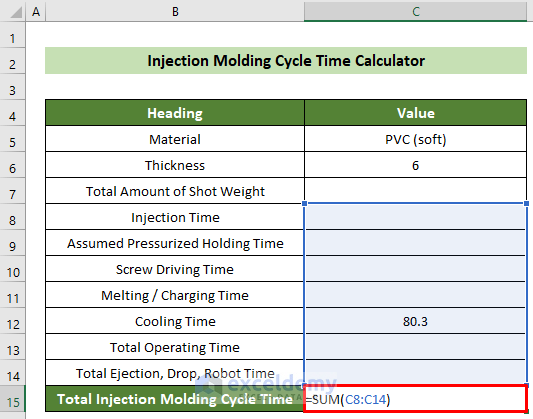

- Click on cells as shown below and insert the required value from your production particulars at the Sample Dataset worksheet.

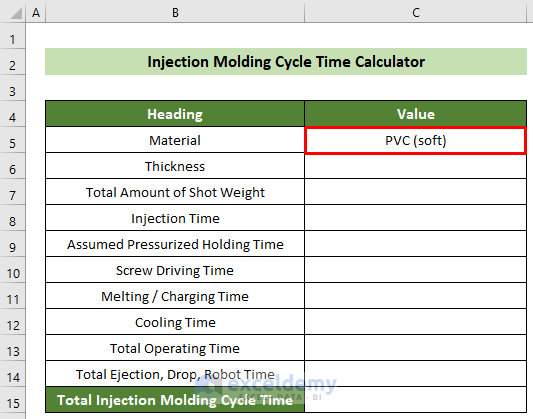

- Click on cell C5 and insert the name of your material (PVC (soft) here).

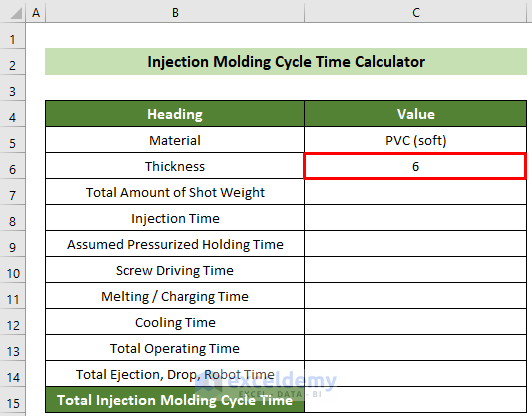

- Click on cell C6 and insert the value for the thickness of your material (6 here).

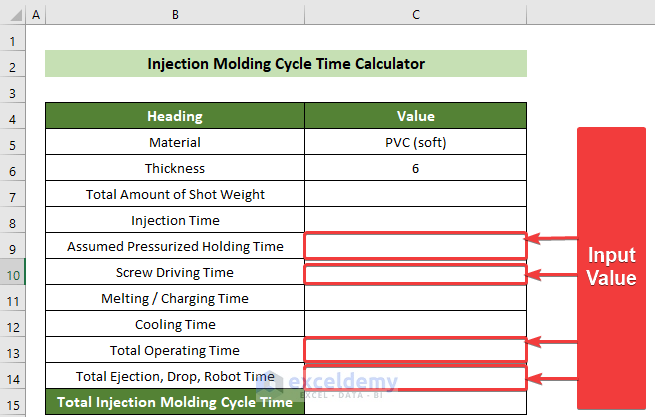

- Insert the required times in the following cells in the image below. You can input these values from the given range in the Sample Dataset worksheet.

Method 2 – Calculate Total Injection Time

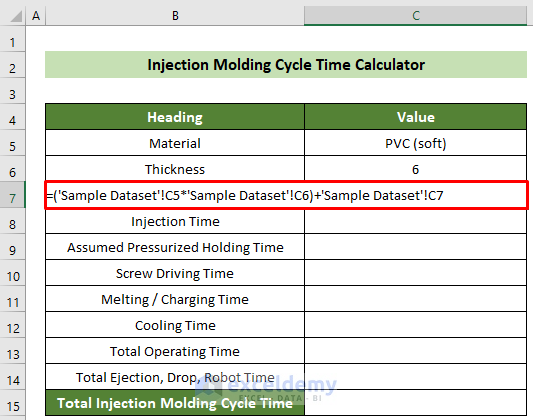

- Click on cell C7 and insert the following formula to calculate the total amount of shot weight.

=('Sample Dataset'!C5*'Sample Dataset'!C6)+'Sample Dataset'!C7- Press the Enter key.

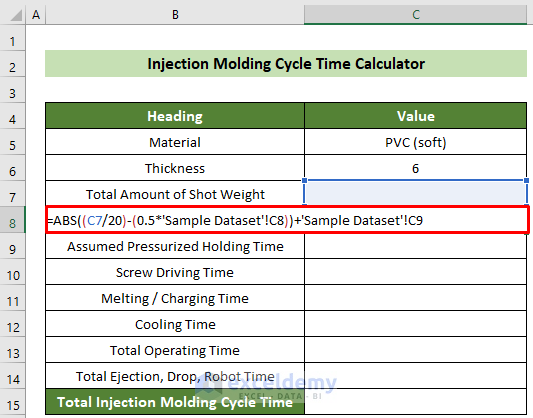

- Click on cell C8 and insert the formula to calculate the total injection time.

=ABS((C7/20)-(0.5*'Sample Dataset'!C8))+'Sample Dataset'!C9- Press the Enter key.

Method 3 – Calculate Total Melting / Charging Time

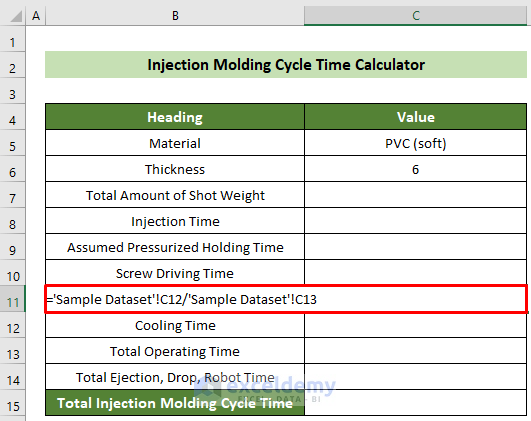

- Click on cell C11 first.

- Insert the following formula and hit the Enter key.

='Sample Dataset'!C12/'Sample Dataset'!C13

Get the total charging time.

Method 4 – Calculate Total Cooling Time

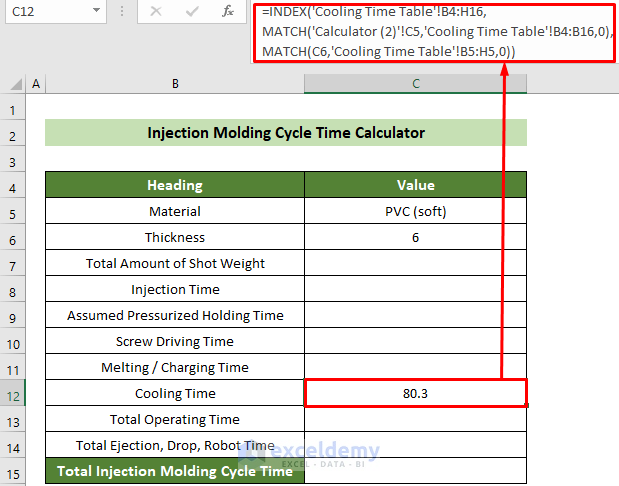

- First and foremost, click on cell C12.

- Insert the formula below.

=INDEX('Cooling Time Table'!B4:H16,MATCH(Calculator!C5,'Cooling Time Table'!B4:B16,0),MATCH(C6,'Cooling Time Table'!B5:H5,0))- Hit the Enter key.

Find the injection molding cycle’s cooling time in the given table.

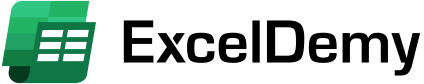

Method 5 – Calculate Total Injection Molding Cycle Time

- Click on cell C15 and insert the following formula.

=SUM(C8:C14)- Hit the Enter key.

Get the total injection molding cycle time. Your injection molding cycle time calculator is ready in Excel. Use the values at the proper cells to automatically find the total injection molding cycle time.

Download Practice Workbook

You can download our practice workbook from here for free!

Related Articles

- Excel Formula for Overtime over 8 Hours

- How to Calculate Hours Worked and Overtime Using Excel Formula

- Excel Formula to Calculate Overtime and Double Time

- Excel Formula To Calculate Time Worked

- Man Hours Calculation in Excel

<< Go Back to Calculate Time | Date-Time in Excel | Learn Excel

Get FREE Advanced Excel Exercises with Solutions!

where did you get the data for cooling times?

Hello, PJ!

Hope you are doing well. Thank you for your query.

Cooling time mainly refers to the time elapsed from the end of holding pressure to the opening of the mold. This value depends on various factors like the wall thickness, product shape, mold temperature, melt properties, etc. To get a better product, the cooling time should be as low as possible.

You can search google thoroughly or visit industrial yards to learn about the actual cooling time values.

Regards,

Md. Tanjim Reza Tanim